CABLE CONSTRUCTION

EHV XLPE Cables

The XLPE cable has Aluminium or Copper conductor, insulated with super clean cross linked polyethylene and then metallic screened with lead alloy sheath (with or without additional copper wires) or corrugated aluminium sheath and covered by PVC or PE for anti corrosion.

a) Conductor

The conductor consists of annealed Copper or hard Aluminium stranded wires. The form of conductor is either stranded compacted circular or milliken (segmental compacted circular). Stranded compacted circular conductor consists of wires stranded together and then compacted. The milliken conductor normally consists of 4 / 5 segments and is normally applied for the conductor sizes above 1000 sqmm. Milliken conductors are used to prevent the increase of A.C. resistance caused by skin effect and proximity effect.

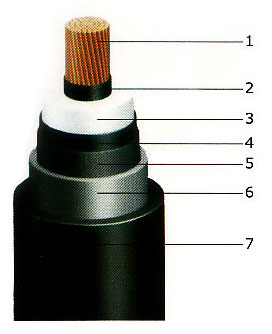

1. Conductor

2. Conductorscreen

3. XLPE insulation

4. Insulation screen

5. Semi conducting water swellable tape

6. Lead alloy sheath (copper wires can be additionally provided below or above the lead sheath)

7. PVCorPE outer sheath

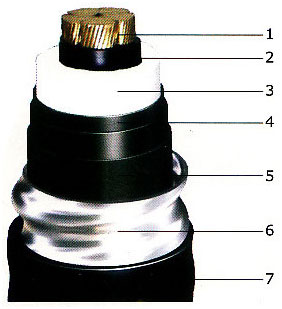

1. Conductor

2. Conductor screen

3. XLPE insulation

4. Insulation screen

5. Semi conducting water swellable tape

6. Corrugated Aluminium sheath with Asphalt coating

7. PVC or PE outer sheath

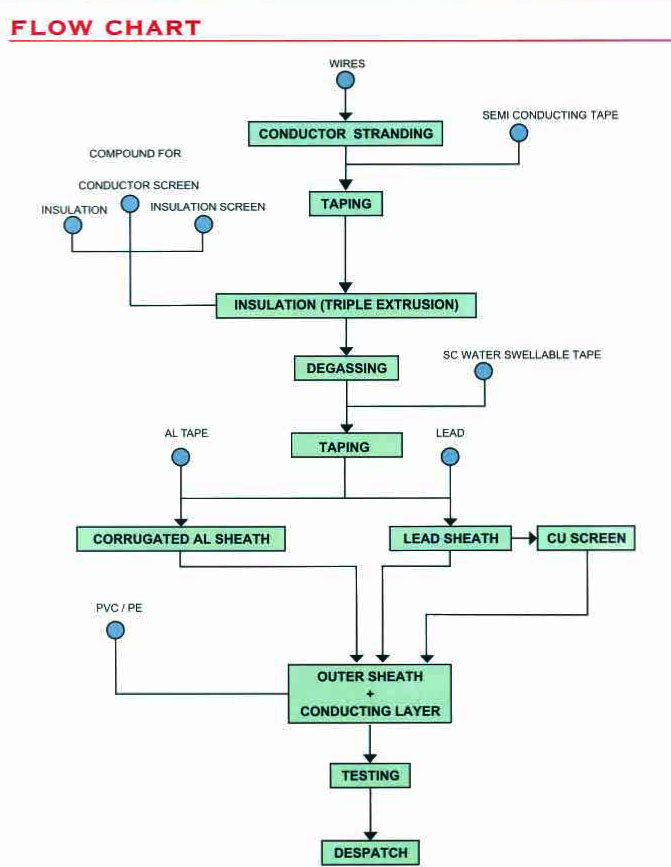

Cable Construction

b) Core Extrusion (Triple Extrusion)

The conductor screen, insulation & insulation screen are extruded simultaneously in Triple Extrusion Process using single (common) cross-head employing Vertical Continuous Vulcanizing (VCV) line with Dry Cure Dry Cool Cross linking Technology. This assures perfect bonding of the semi conducting layers with insulation in order to eliminate chances of micro void formation.

b-1) Conductor Screen

The conductor screen consists of an extruded layer of semi conducting compound. The conductor screen not only eliminates the risk of electrical discharge at the interface between conductor and insulation but also presents a very smooth interface with the Insulation to eliminate any localized stress concentration.

b-2) Insulation

The insulation material is extruded cross linked polyethylene and applied over the conductor screen in a strictly controlled atmospheric conditions. The cross linking process by dry (nitrogen gas) curing has enabled to protect the electrical characteristics from being deteriorated.

b-3) Insulation Screen

The insulation screen is provided over the insulation by extruding the semi conducting compound concentrically to minimize the possibility of ionization on the outer surface of the dielectric. Extruded semi conducting layer Is followed by a semi conducting non-woven water swellable tape.

c) Metallic Screen

The metallic screen consists of corrugated aluminium sheath or lead alloy sheath. In case of lead sheath design additional copper wire may be provided If lead alloy sheath alone Is not sufficient to meet the requirement of earth fault current.

d) Outer Sheath

To protect the metallic sheath from electrochemical or galvanic corrosion, it is covered by PVC or PE.

e) Conductive outer layer

A conductive outer layer facilitates testing of the non metallic outer sheath. This test is

important to ensure the physical integrity of the cable.

PROCESS

Extrusion & Curing Process

The system adopted for insulation of EHV XLPE cable is Vertical Continuous Vulcanizing (VCV) and DCDC (Dry Curing and Dry Cooling) for cross-linking. The VCV line with triple extrusion ensures excellent concentricity of the cable coupled with a compact insulation with perfect contact between the layers and hence superior dielectric properties at very high voltages. On-line monitoring and controls in the production process ensures adherence to specified and strict dimensional standards. The DCDC process adopted for cross linking ensures that the insulation Is kept absolutely dry during the curing process. This eliminates the chances of electrochemical treeing during the full life of the cable. The outstanding characteristics of XLPE cables manufactured by VCV line are:

- Fully concentric insulation,

- The dry cured and dry cooled cross linking by use of nitrogen gas guarantees excellent electrical characteristics of the insulation,

- The simultaneous extrusion of the inner and outer semi conducting layers and the insulation prevents void formation,

- Computerized controlled manufacturing processes maintain uniformity of quality.